Step by Step Guide : How to exchange variable between safety controller and non safe controller (NJ/NX) using Sysmac Studio

Introduction

The purpose of this document is to demonstrate how to configure NX safety PLC with NJ MAC and exchanged variables between safety controller and main controller

Pre-Requisites

The programmer should have very good understanding of Sysmac and Safety programming

Further Reading

Procedure

Step1

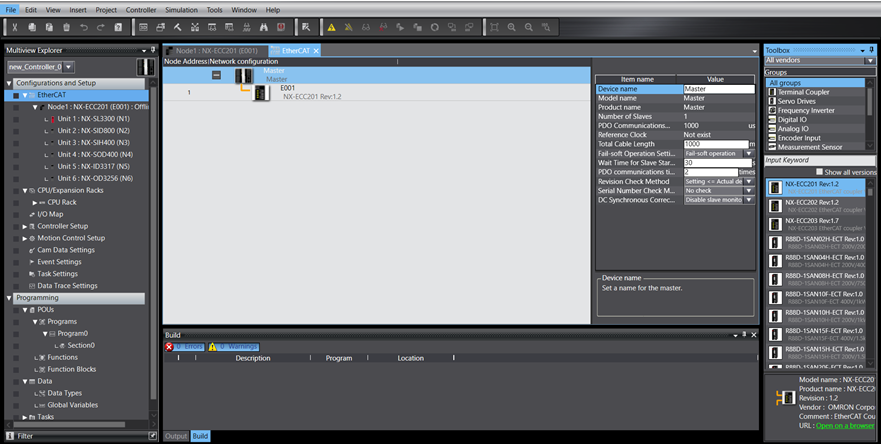

Adding NX-ECC coupler in Sysmac

Double click EtherCAT and add ECC coupler by dragging it from Toolbox

Step 2

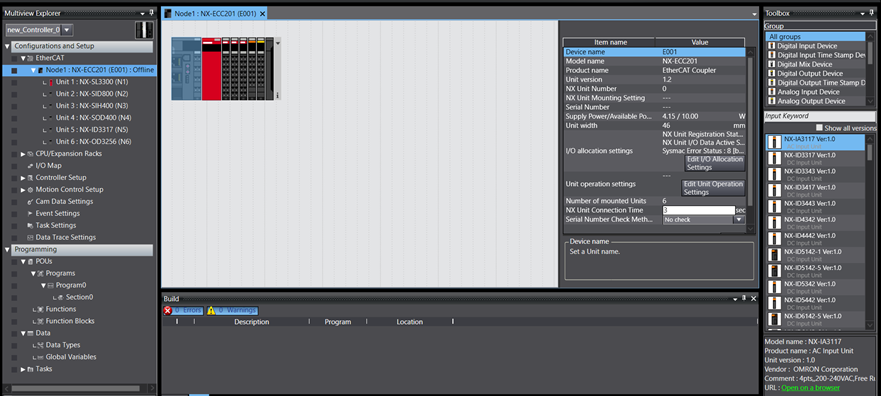

Add safety controller and IOs

Double click Node 1 NX-ECC under EtherCAT and drag all the required hardware from the toolbox list including SL3300 (mandatory) ,SID800 (mandatory), SIH400, SOD400, ID3317, OD3256

Step 3

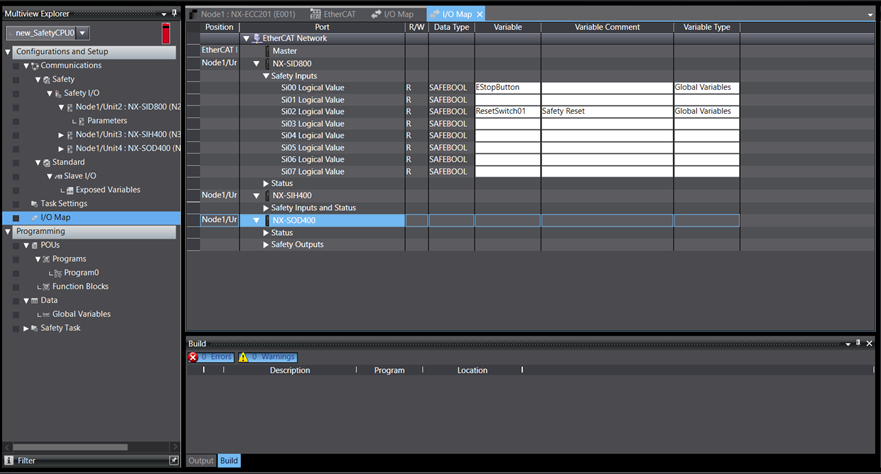

Creating safety variable

Go to the new_SafetyCPU and select I/O Map. Provide the variable name for Si00 and Si02 as EstopButton and ResetSwitch01 respectively

Step 4

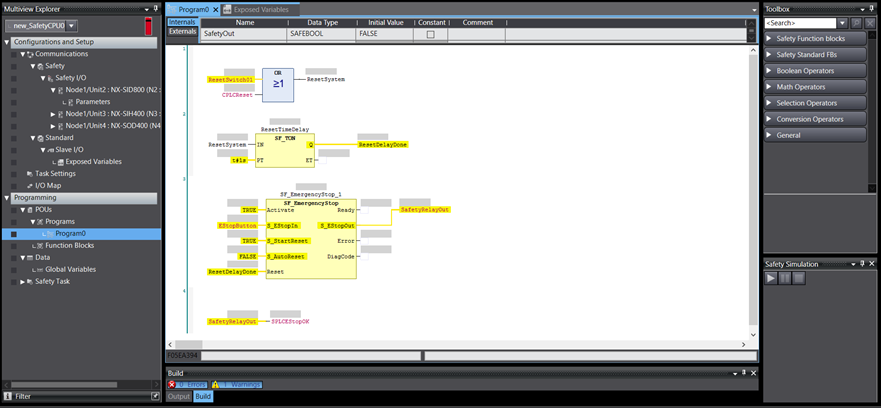

Writing Safety Program

Double click Program0 on safety controller and drag logical OR & two safety Function Blocks.

1. SF_TON

2. SF_EmergencyStop.

Insert all the variable as provided in the picture below. *SafetyRelayOut is the dummy safe variable

Step 5

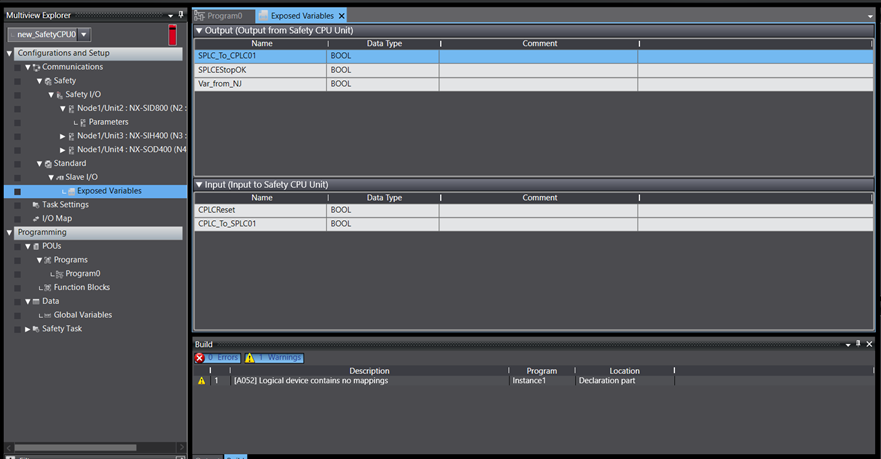

Creating exposed variable

Double click on Exposed Variables and create variables as shown in the image

Step 6

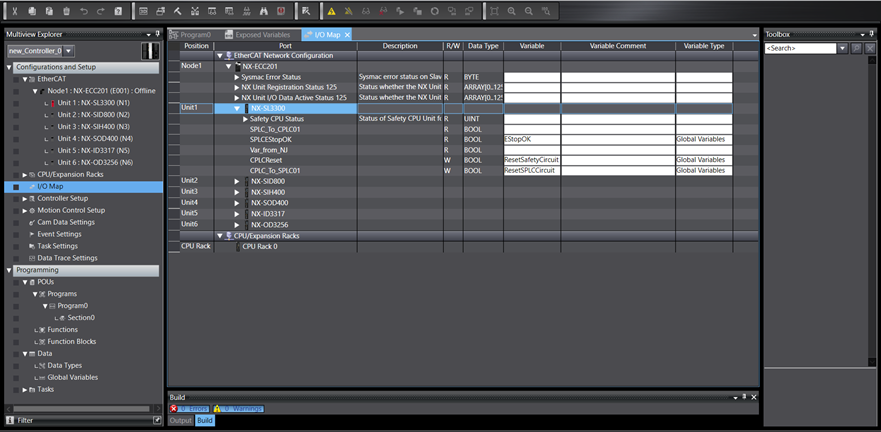

Variable mapping

Create a variable name for the exposed variable as “EStopOK” and “ResetSafetyCircuit”

Step 7

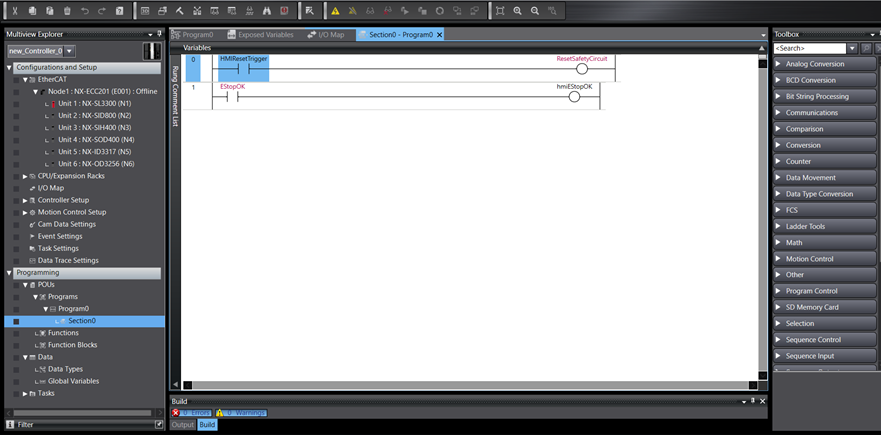

Go to non-safe PLC and create a small logic as below to verify variable transmission

Step 8

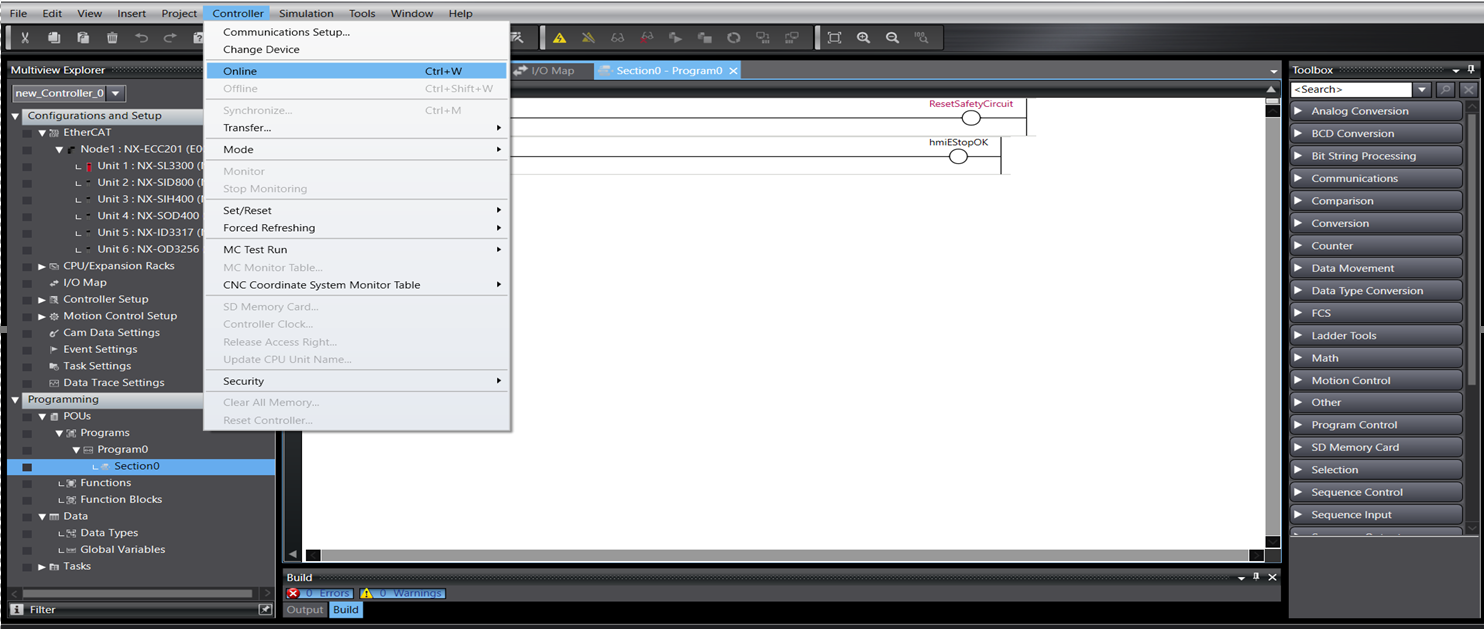

Go online and transfer the program to verify

End of step by step guide