How to teach Multiple Robots Conveyor Tracking Pallet Process using ACE Versions lower than 3.8.3.160.

Introduction

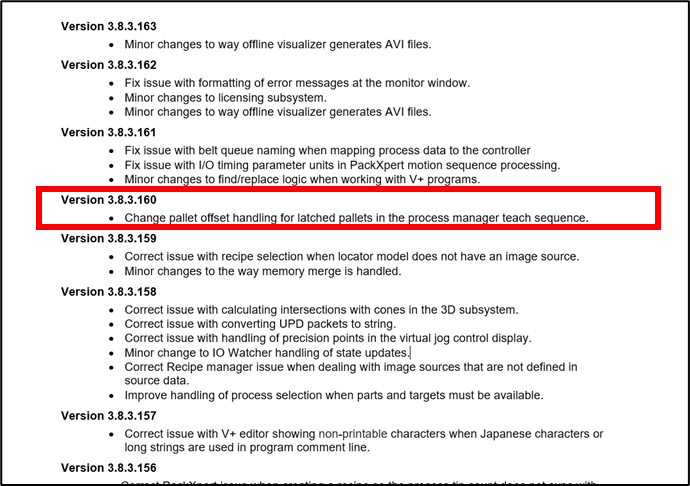

Pallet offset handling for latched pallets in the process manager teach sequence has been improved from ACE 3.8.3.160 version and above.

When this change has been made, the offset, since then, was being applied to the specific robot being taught instead of the pallet’s “Offset to First Slot” property.

Before Change

Before Change

After Change

After Change

For older systems using lower ACE versions, the steps below should be followed to successfully teach the Robots offsets without affecting the Pallet’s “Offset to First Slot” property.

Configuration:

Multiple Robots System processing a common pallet on a conveyor belt.

Pick or Place Process with pallet located by a belt latch sensor.

Steps:

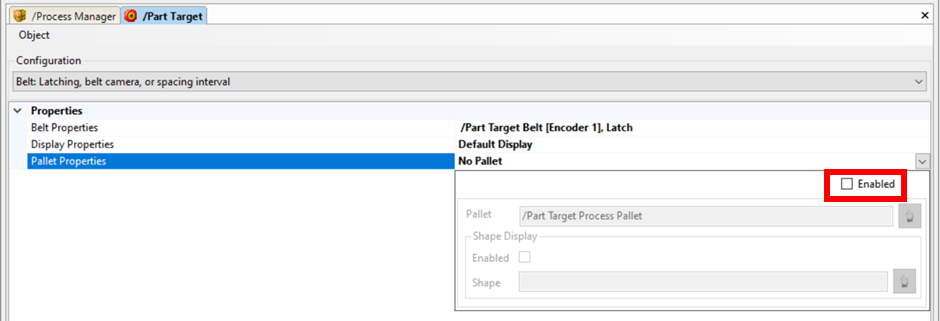

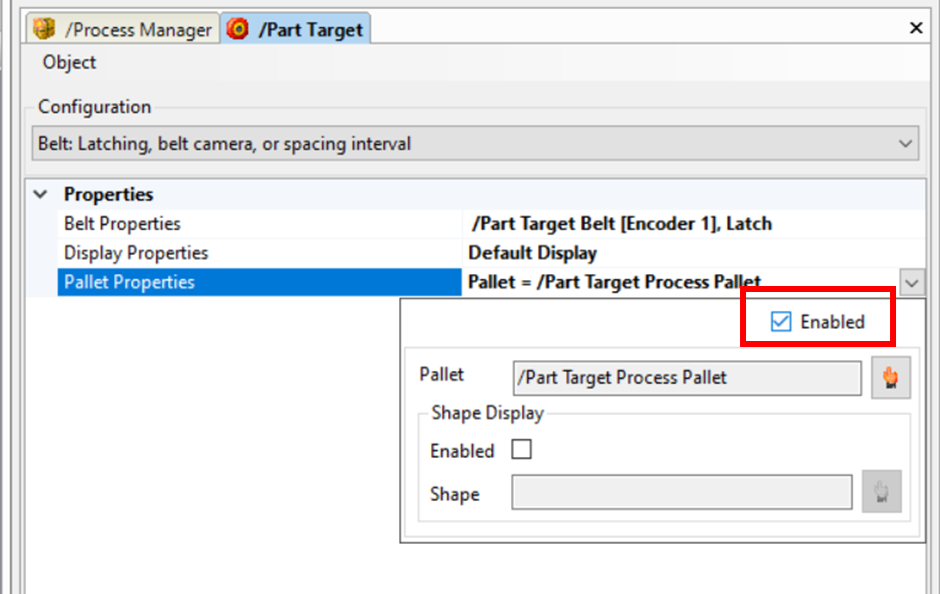

1. Disable the Pallet from the Pick/Part Target Pallet Properties before Teaching/Reteaching the Process.

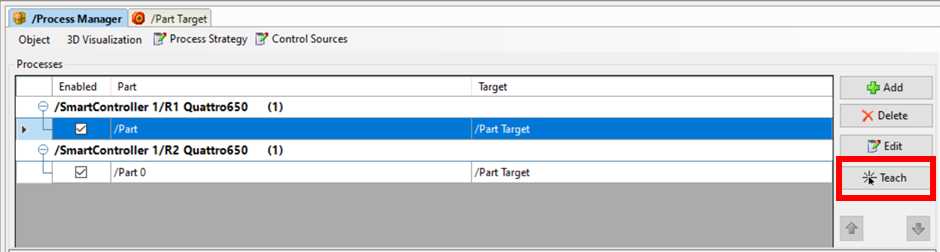

2. Reteach the processes. (Please refer to ACE User Guide for more details)

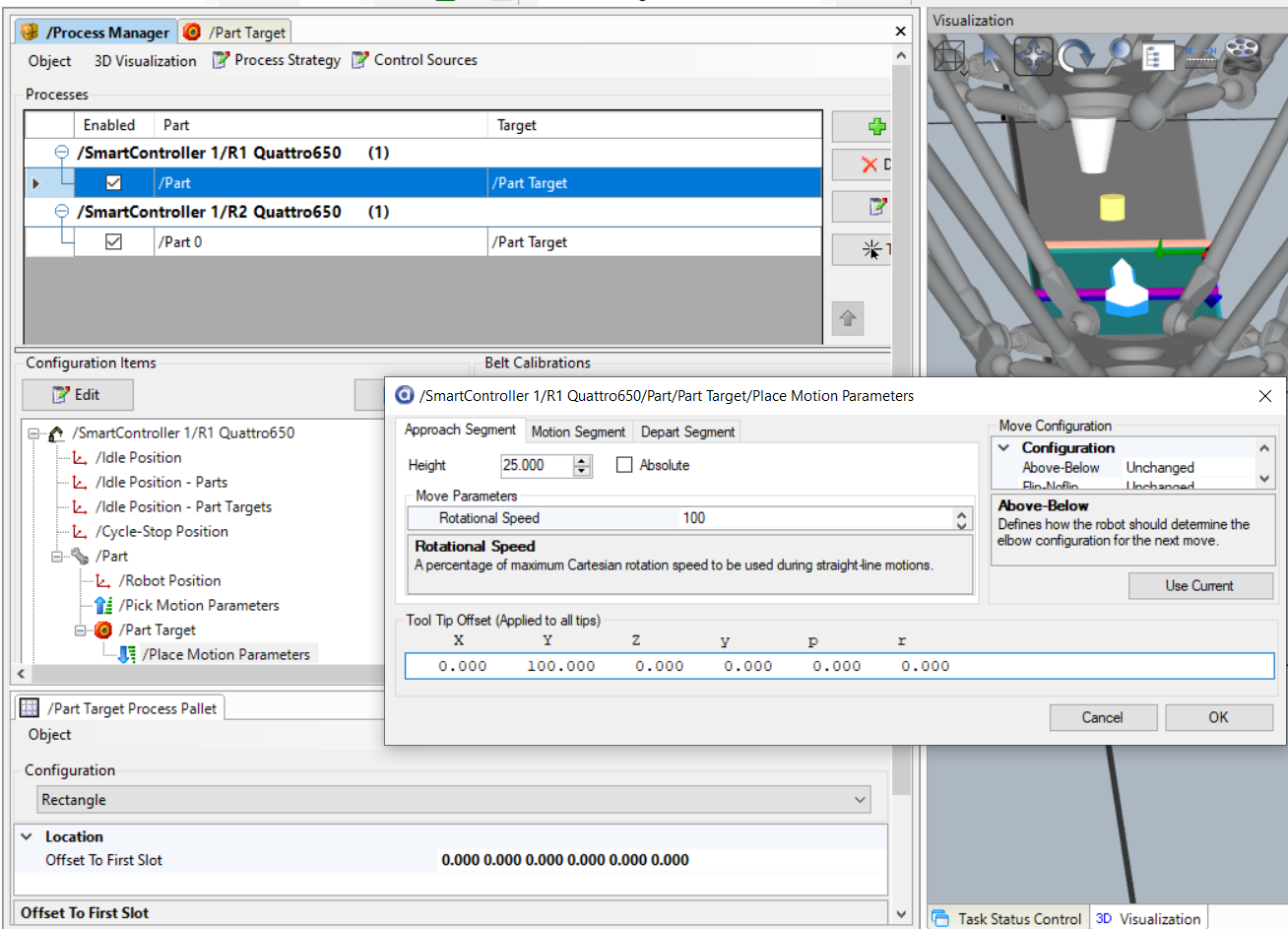

Resulting Tool Tip Offset will be applied to the Robot after teaching:

3. Re-enable the Pallet from the Pick/Part Target Pallet Properties:

4. Test the Process to verify that the offsets are correct.